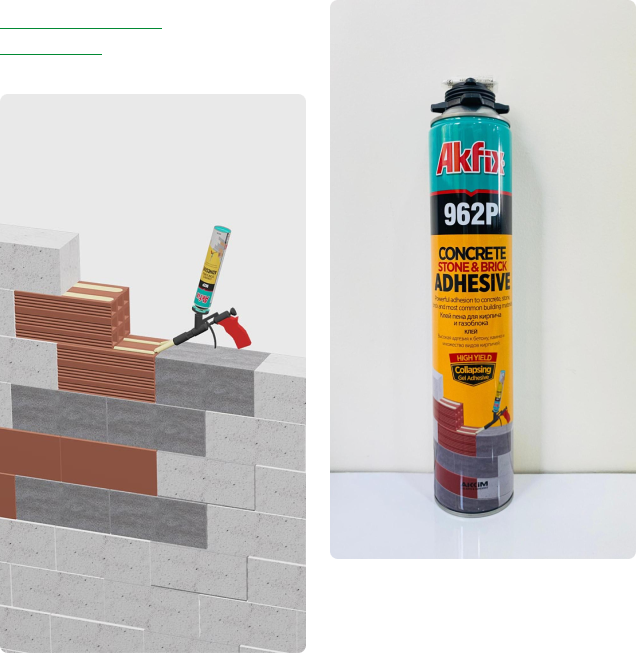

We are the Exclusive Distributor of Akfix 962P PU Adhesive in India

Akfix 962P PU Adhesive is a specialized adhesive foam designed for bonding construction elements such as Concrete Stone. GEOBLOCKS is proud to be the Exclusive Marketer and Distributor of Akfix 962P Concrete Stone PU Adhesive in India, ensuring premium quality for your construction needs.

- Eco-friendly Adhesive Solution

- Easy-to-apply PU Adhesive

- Fast Curing for Efficient Results

- Minimal Expansion after Drying

Build smarter with GEOBLOCKS! Request a free price quote now and find out how our Akfix 962P can provide exceptional quality at the best price. Contact us today!

Features of Akfix 962P

PU Foam Adhesive is a cutting-edge bonding solution designed to meet the diverse needs of Construction and Renovation Projects. Known for its Ease of Use and Strong Performance, it offers a Range of Features that make it an Ideal Choice for Professionals.

- A special product which is transforming with collapsing from foam form to gel adhesive form in a couple of seconds after application.

- One component, is fast curing, easy-to-use adhesive foam.

- Bonding blocks and stones during construction works.

- Powerful adhesion to concrete and stone variations.

- Suitable to use for interior and exterior applications.

- Remarkable resistance to weather conditions.

- More economical, practical and easy to use.

- Minimum expansion during drying period.

- No more extra burden or weight to building.

- Usable at low temperature like +5 °C.

- It does not contain any propellant gases which are harmful to the ozone layer.

Applications of Akfix 962P

PU Foam Adhesive is a Versatile Bonding Solution suitable for a Wide Range of Applications in Construction and Renovation. Its Unique Properties allow it to Effectively Bond Various Materials, making it an Ideal Choice for Professionals and DIY Enthusiasts. Here are Some Common Applications:

- Bonding structural blocks of non-bearing interior walls.

- For use where fixed, permanent positioning of stone or concrete products is desired.

Usable on

- Concrete pavers/slabs

- Segmental retaining walls and columns

- Cast stone copings

- Landscape blocks and bricks

- Polystyrene foam board

- Cellular lightweight concrete elements

- Ornamental precast

- Natural & manufactured stone

- Brick, aerated block, cinder block, bits block, gypsum block and gypsum panel bonding

Instructions of Akfix 962P

To ensure optimal performance and effective bonding with Akfix 962P PU Adhesive, it’s important to follow specific guidelines during application. Proper preparation and application techniques will help you achieve the best results in your construction projects.

Below are essential instructions to help you use the adhesive effectively:

- Optimal can temperature is +20 °C.

- Optimal application temperature is in between +5°C and +30 °C.

- Shake the can well before use. Screw the can onto an applicator gun.

- The outflow of the foam can be regulated with the trigger and controlled with the adjustment screw on the back side of the gun.

- Always keep the can upside down during application.

- Surfaces must be clean and free of oil or dust.

- It can adhere to even slightly damp surfaces.

- Apply the foam in between stones and use a little bit force to fix the materials. A plastic head hammer can be used.

- The amount of the foam that will be used depends on the thickness and weight of the stone.

- For a better appearance it is not recommended to apply the foam to the edges and corners of the stone. At least 2 or 3 cm gap must be left on the edges and corners and the foam should be applied to inner sides of the stone.

- Fresh foam can be cleaned by Akfix Foam Cleaner. Cured foam can be cleaned barely mechanically.

Build smarter with GEOBLOCKS! Request a free price quote now and find out how our Akfix 962P can provide exceptional quality at the best price. Contact us today!

Restrictions of Akfix 962P

While Akfix 962P PU Adhesive offers exceptional bonding capabilities, it is essential to adhere to certain restrictions to ensure its effectiveness and longevity. Proper storage and handling practices will help maintain the adhesive’s performance and prevent any issues during application.

Below are key restrictions to keep in mind when using this product:

- Storage above +30 °C and below +5 °C shortens shelf life.

- Should be stored and transported in vertical position.

- Should be kept in room temperature for at least 12 hours before the application.

- Cured foam will discolor if exposed to ultraviolet light.

- Paint or coat the cured foam for best results in outdoor applications.

- Dried foam can be wiped out by mechanical force.

- Lower temperatures decreases yield and curing time.

Safety of Akfix 962P

Safety is important when using Akfix 962P PU Adhesive, as it contains chemicals that may pose health risks if not handled properly. To ensure a safe working environment and to protect yourself from potential hazards, it is crucial to follow these safety instructions diligently.

Below are essential precautions to take when using this product:

- Contains Diphenylmethane-4, 4’-Diisocyanate. Harmful by inhalation. Irritating to eyes, respiratory system and skin.

- Do not breathe spray/vapor. Use only in well-ventilated areas.

- Wear suitable protective clothing and gloves.

- Pressurized container. Keep away from direct sunlight and do not expose temperatures over 50 °C.

- Do not pierce or burn, even after use.

- Keep away from sources of ignition, no smoking.

- Keep out of the reach of children.

Properties of Akfix 962P

Understanding the Technical Specifications of PU Foam Adhesive is essential for Maximizing its Performance in Various Applications. This Innovative Adhesive is Engineered with a Unique Formulation that ensures Superior Bonding Capabilities, Efficiency, and Durability. Below are the Key Specifications, which enable Users to make Informed Decisions for their Construction and Renovation Projects.

- One component, fast curing, easy to use adhesive foam.

- Bonding blocks and stones during construction works.

- Powerful adhesion to concrete and stone variations.

- Suitable to use for interior and exterior applications.

- Remarkable resistance to weather conditions.

- Not form thermal bridges, thanks to the excellent thermal insulation.

- Thanks to the modern chemical formulation does not drip on vertical surfaces. (In accordance with the current regulations).

- More economical, practical, and easy to use.

- Minimum expansion during the drying period.

- After drying, no further expansion or shrinkage.

- No more extra burden or weight to the building.

- Usable at low temperatures like +5 °C.

- It does not contain any propellant gases which are harmful to the ozone layer

| Basis | Polyurethane Prepolymer |

| Curing System | Moisture Cure |

| Tack-Free Time | 5-8 min (ASTM C1620) |

| Cure-Time | 24 hours |

| Foam Color | Light Yellow |

| Metric yield | 120 meters in (1.3 cm) bead |

| Shelf life | 12 months |

| Fire Class of the Cured Foam | B3 (DIN 4102-1)(EN 13501-1) |

| Shear Bond Strength | >12 MPa |

| Temperature Resistance | -40°C to +90°C |

| Application Temperature | +5°C to +30°C |

Frequently Asked Questions

Akfix 962P PU Foam Adhesive stands out for its Exceptional Bonding Strength, Fast Curing Time, and Versatility in Various Applications. As the sole Marketer and Distributor in India, GEOBLOCKS guarantees you access to a High-quality Product that meets all your Construction Needs.

The Curing Time for PU Foam Adhesive is Approximately 24 Hours.

Absolutely! PU Foam Adhesive is designed for both interior and exterior applications. Its remarkable resistance to weather conditions ensures a strong bond, making it ideal for a wide range of projects, from wall installations to landscaping.

The Ideal Temperature Range for Application is Between +5°C and +30°C.

This Versatile Adhesive can Bond Various Materials, including Concrete, Stone, Aerated Blocks, AAC Wall Panels, and EPS Sandwich Panels.

Use the Akfix 800C Foam Cleaner for Fresh Foam; Cured Foam requires Mechanical Removal.

PU Foam Adhesive does not contain Harmful Propellant Gases that affect the Ozone Layer. By Choosing our Eco-friendly Adhesive, you contribute to Sustainable Building Practices while Enjoying Excellent Performance.

You can Easily Purchase Akfix 962P PU Foam Adhesive by Contacting our Team at +91 7600521228 or from Our Website.

Video Gallery

Get in touch

Feel free to contact us with a project proposal, quote or estimation, or simply to say hello. Here’s our contact info.