In today’s world of smart construction and sustainable living, insulation plays a crucial role in…

When it comes to construction, the strength and durability of materials are paramount. Concrete blocks, widely used in various construction projects, are no exception. One of the most critical aspects of concrete blocks is their compressive strength, which determines their ability to withstand loads without cracking or breaking. GEOBLOCKS, a leading Concrete Block Manufacturer in Vadodara, understands the importance of quality in construction materials. In this blog, we’ll guide you through the process of testing the compressive strength of concrete blocks to ensure they meet the required standards.

Why is Compressive Strength Important?

The compressive strength of a concrete block is a key indicator of its overall performance and suitability for construction. Blocks with high compressive strength can bear heavy loads, making them ideal for structural applications. Ensuring that your concrete blocks meet the required compressive strength is essential for the safety, stability, and longevity of any building or structure.

Step-by-Step Guide to Testing Compressive Strength

Sample Preparation

Selection of Samples: Choose representative samples from the batch of concrete blocks. Typically, three blocks are selected for testing to ensure accuracy and consistency.

Conditioning: Before testing, the blocks should be conditioned by soaking them in water for 24 hours to achieve a saturated surface dry condition. This helps to standardize the moisture content across samples.

Measurement of Dimensions

Measure Dimensions: Using a caliper, measure the length, width, and height of the concrete blocks. This is important to calculate the cross-sectional area, which is used in determining the compressive strength.

Positioning in the Testing Machine

Place the Block: Position the concrete block on the testing machine’s platen, ensuring that the load will be applied uniformly across the surface. The block should be centered, and its surfaces should be level.

Capping: If the block surfaces are uneven, capping with a thin layer of cement paste or using a steel plate may be necessary to ensure even load distribution.

Applying the Load

Start the Machine: Gradually apply the load using a compression testing machine. The load should be applied steadily at a rate of 2.5 kN/sec until the block fails or cracks.

Recording the Maximum Load: Note the maximum load the block can withstand before failure. This value is crucial for calculating the compressive strength.

Calculation of Compressive Strength

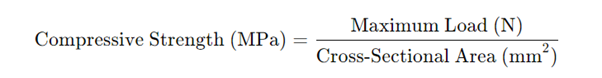

Use the Formula: The compressive strength is calculated using the formula:

Analyze the Results: Compare the calculated compressive strength with the required standard for the specific application. The strength should meet or exceed the minimum required values set by relevant standards (e.g., IS 2185 for India).

Reporting the Results

Document Findings: Record all relevant data, including the sample dimensions, maximum load, calculated compressive strength, and any observations during testing. This documentation is essential for quality control and certification purposes.

Conclusion

Testing the compressive strength of concrete blocks is a vital step in ensuring that they are fit for construction purposes. At GEOBLOCKS, we prioritize quality and adhere to rigorous testing standards to produce concrete blocks that meet the highest industry benchmarks. As trusted Concrete Block Manufacturers in Vadodara, we are committed to delivering durable and reliable construction materials to our customers.